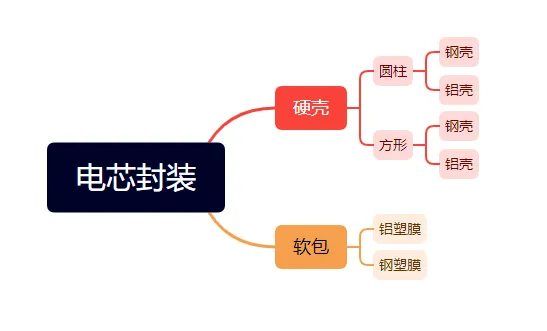

Lithium-ion batteries are categorized into square batteries, flexible pack batteries cylindrical batteries according to the encapsulation process.The current market is dominated by square batteries.

Digital products mainly use soft pack batteries, cylindrical batteries as cost-effective products to fill the market share.

This article explains the lithium-ion battery packaging form, together with the advantages disadvantages of different technical routes.

一

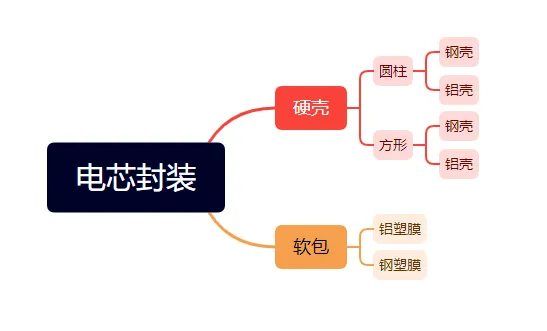

Cell Packaging

Lithium-ion batteries are divided into two categories, hard case soft pack, according to the different s of the cells. The materials of the hard are mainly steel aluminum s, while the soft pack uses aluminum-plastic composite film material. Among them, the hard case is further divided into cylindrical square according to the arrangement of positive negative pole pieces inside.

Soft pack lithium battery

Soft pack lithium batteries are just liquid lithium batteries packaged in a polymer . Structure type ion of aluminum-plastic film packaging, in the case of safety security hazards arising from the soft pack battery at most will be bulging cracking.

Hard pack lithium batteries

Hard pack lithium batteries are subdivided into two types: cylindrical square. The structure of the package has different advantages disadvantages, mainly for different market dem places. Hard pack lithium battery consistency is relatively difficult to ensure that more more models, the processing process is difficult to be completely consistent, suitable for customized production manufacturing, is not convenient for lithium battery pack automated production.

二

Soft pack lithium battery process

Flexible pack cells, in fact, are cells that use aluminum-plastic packaging film as a packaging material. The size change is flexible, the cost is low, the energy density of a single cell is higher than that of both cylindrical/square cells. Soft pack cells are thermally encapsulated due to their use of aluminum-plastic packaging film as a material.

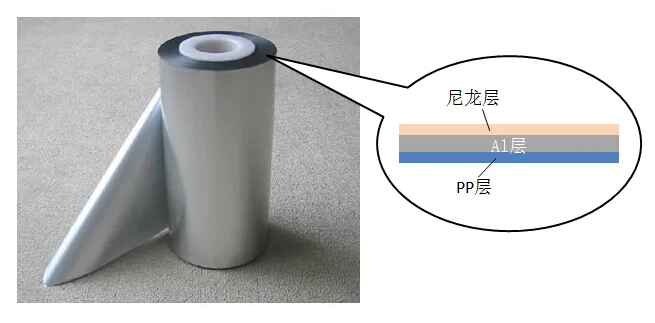

#Aluminum packaging film#

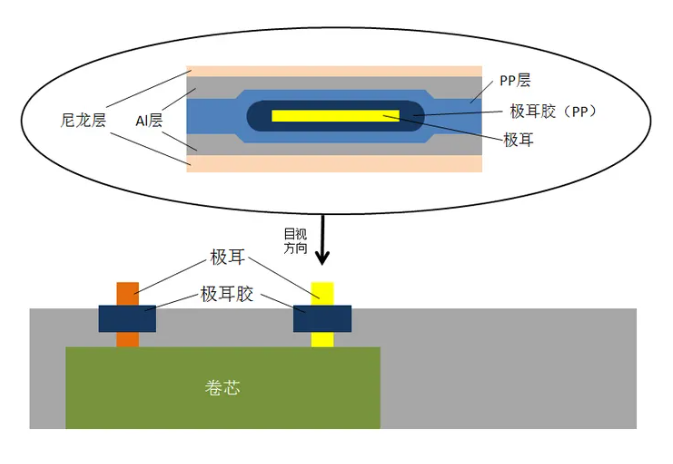

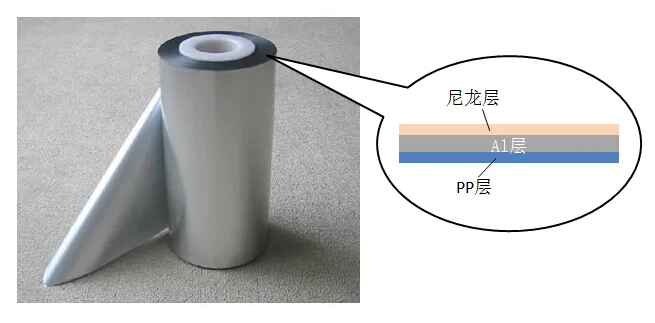

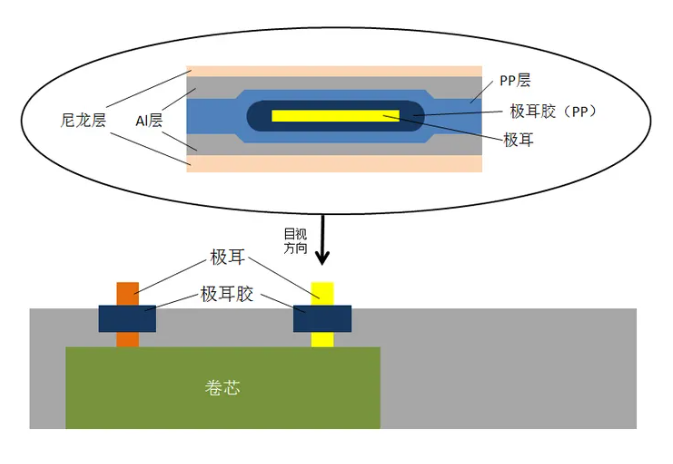

Aluminum-plastic packaging film (referred to as Aluminum-plastic film), its cross-section of three layers: nylon layer, A layer PP layer.

Each of the three layers has its own role, first of all, the nylon layer is to ensure the shape of the aluminum-plastic film, to ensure that the film will not be deformed before the manufacture of lithium-ion batteries.

The AI layer is a layer of metal AI composition, its role is to prevent water infiltration. Hammer ion batteries are very afraid of water, generally require that the water content of the pole piece are at the PPM level, so the packaging film must be able to block the penetration of moisture. Nylon is not waterproof cannot provide protection. Instead, metal AI reacts with oxygen in the air at room temperature to generate a dense oxide film, resulting in moisture not being able to penetrate protecting the inside of the cell. the AI layer also provides the plasticity of the punching pits when the aluminum-plastic film is formed.

PP sts for polypropylene, a material characterized by melting at temperatures of more than one hundred degrees Celsius viscosity. So the thermal encapsulation of the battery relies mainly on the PP layer melting bonding together under the heat of the header, then the header is withdrawn the bond is cured by cooling down.

#Aluminum-plastic film forming process#

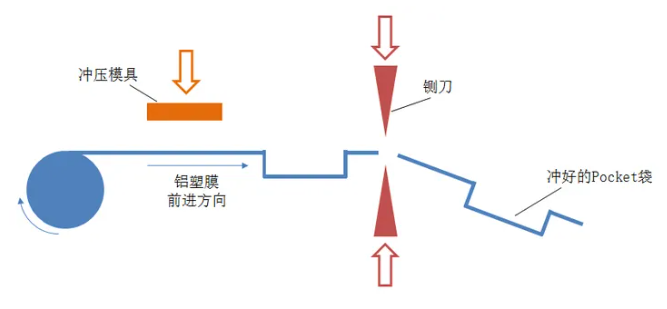

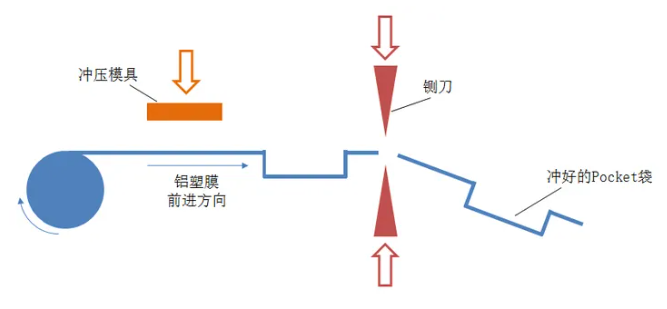

FPCs can be designed in different sizes according to customers' needs. When the dimensions are designed, it is necessary to open the corresponding molds to make the aluminum-plastic film forming. The molding process is also called punching. As the name suggests, it is to use the forming mold to punch out a pit on the aluminum-plastic film under the condition of heating to be able to load the core.

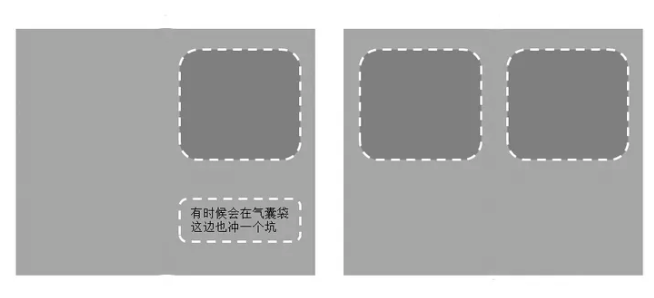

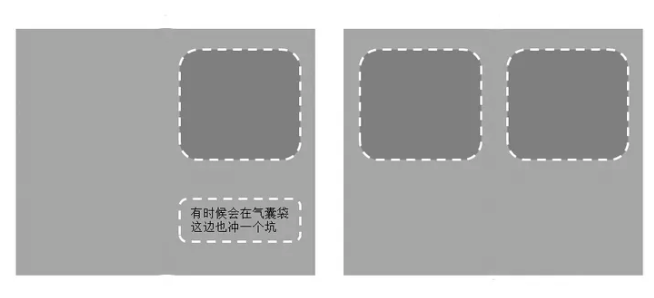

After the aluminum composite film is punched cut to shape, generally known as Pocket Pockets, it is generally chosen to punch a single pit (left in the picture below) when the electrode is thin, double pits (right in the picture below) when the electrode is thicker because the deformation of one side is too large to break through the deformation limit of the aluminum composite film lead to rupture.

Sometimes, depending on the design, another small pit is punched where the air bag is to exp the volume of the air bag.

#topside sealing process#

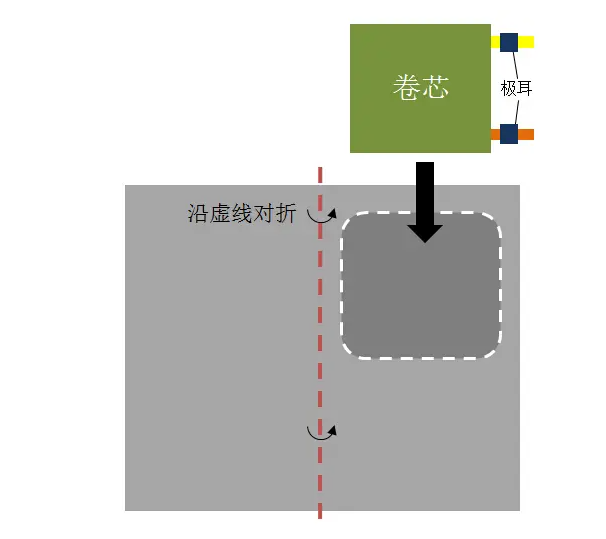

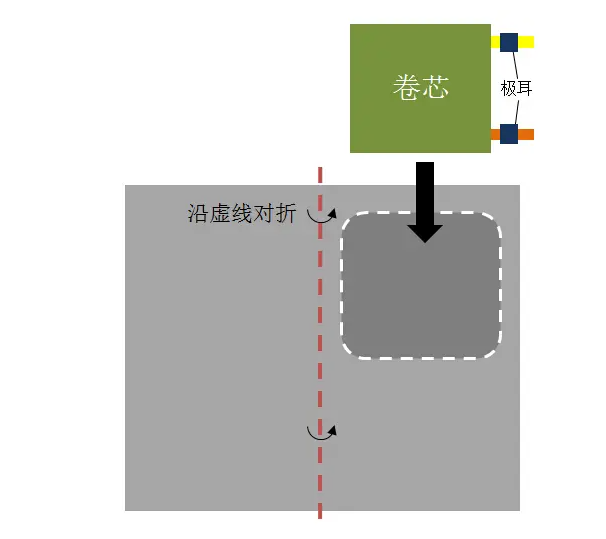

The top-side sealing process is the first encapsulation process of soft pack lithium-ion battery cell. Top side sealing actually contains two processes, top sealing side sealing. Firstly, the coiled core is put into the punched pit, then the packaging film is folded along the dotted line.

Once the core is placed in the pit, the entire aluminum composite film can be placed in the fixture for top side sealing in the top side sealing machine.

This type of top side sealing machine with four fixtures, the left station is top sealing, the right station is side sealing. The two pieces of yellow metal is the top sealing head, there is a lower sealing head, when encapsulation of the two sealing head with a certain temperature (generally around 180 ° C), closed when pressed on the aluminum-plastic film, aluminum-plastic film PP layer melted then bonded together, so that the encapsulation is OK.

Then we will talk about the top sealing, the diagram of the top sealing area is shown in the figure below. Top seal is to seal the lugs, lugs are metal (positive aluminum, negative nickel), how to encapsulate with PP together?

This is to rely on a small part of the lugs on a lug adhesive to complete. The lug adhesive also has the cost of PP, which means that it can melt bond when heated. The encapsulation of the lugs is shown in the circle in the figure below. During encapsulation, the PP in the lug adhesive melts bonds with the PP layer of the Aluminum Composite Film to form an effective encapsulation structure.

#Liquid injection pre-sealing process#

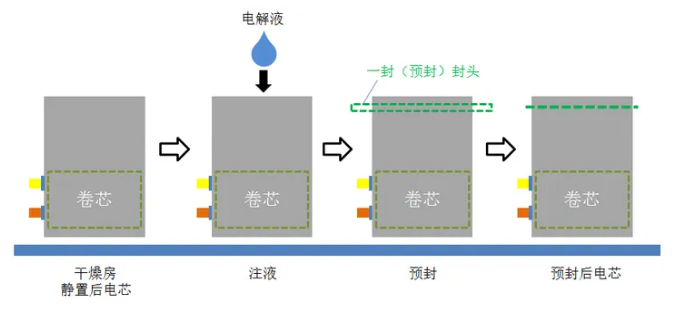

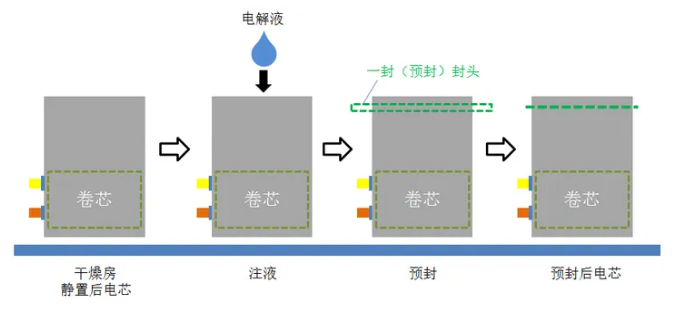

After the top side sealing of the soft package electric core, it needs to do X-ray to check the parallelism of the core, then it goes into the drying room to get rid of the water gas. In the drying room, it will enter into the liquid injection pre-sealing process after a certain period of time.

After the top side sealing of the core is completed, there is only one opening left on the side of the air pocket, this opening is used for liquid injection. After the liquid injection is completed, it is necessary to immediately carry out the pre-sealing of the air bag side, also known as an encapsulation. After the completion of one seal, the core is theoretically completely isolated from the external environment. The encapsulation principle of one seal is the same as that of the top side seal, will not be explained again.

#Static, chemical jig shaping processes#

After the liquid injection a letter is completed, the first need to be static core, according to the different processes will be divided into high-temperature static room temperature static, the purpose of static is to let the injected electrolyte fully infiltrate the pole piece. Then the core can be taken to do the chemical formation.

The picture above is the formation cabinet of the soft pack battery cell, which is actually a charging discharging device. Formation is the first charging of the battery cell, but it will not be charged to the highest voltage for use, the charging current is also very small. The purpose of formation is to let the electrode surface form a stable SEI film, which is equivalent to a process of "activation" of the battery cell.

During this process, a certain amount of gas is generated, which is why an air pocket is reserved for the aluminum-plastic film. Some factories will use the process of fixture formation, that is, the core clamped in the fixture (sometimes figure easy to use a glass plate, then on the steel clamps) then on the cabinet formation, so that the gas will be sufficiently squeezed to the side of the gas bag to go, at the same time after the formation of the electrode interface is also better.

After forming, some cells, especially thick cells, may be deformed due to high internal stress. Therefore, some factories will set up a fixture shaping process, also called fixture baking (baking), after the formation.

#secondary sealing process#

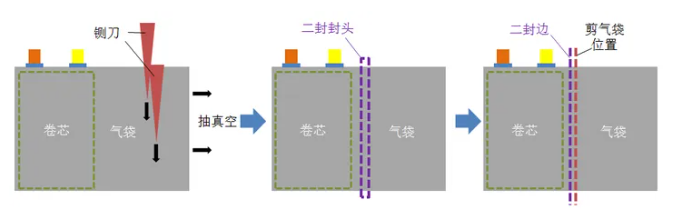

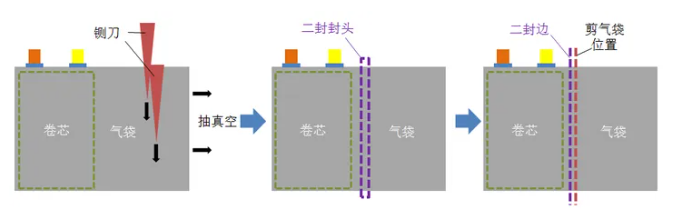

Gas will be generated during the formation process, so the gas has to be extracted then encapsulated for the second time. Here some companies become two processes: Degassing (exhaust) second sealing, there is also a later process of cutting the gas bag, here are generally referred to as second sealing.

When second sealing, the gas bag is first pierced by the guillotine vacuumed at the same time, so that the gas in the gas bag with a small part of the electrolyte will be pumped out.

Then immediately the second sealing head ° in the second sealing area for encapsulation, to ensure the gas tightness of the electric core. Finally, the encapsulated core cut off the gas bag, a soft pack battery cell is basically molded. The second seal is the last encapsulation process of the hammer ion battery, its principle is still the same as the previous thermal encapsulation, will not be described.

This article mainly explains the encapsulation, the back of the encapsulation has little to do, so the process after the second seal is briefly summarized:

After sealing cutting the air bag needs to be cut folded, that is, one edge two edges cut to the appropriate width, then folded up to ensure that the width of the core does not exceed the stard. After the folding of the core can be on the sub-capacity cabinet for sub-capacity, in fact, is the capacity test to see whether the capacity of the core has not reached the minimum value of the regulations. In principle, all batteries need to be tested before leaving the factory to ensure that unqualified batteries will not be sent to customers. However, when the production volume of battery cells is large, some companies will do part of the split capacity to determine the capacity of the batch of battery cells to pass the rate of statistical probability.

After dividing the capacity, the qualified cells will enter the post-process, including checking the appearance, pasting the yellow glue, side voltage testing, pole lug welding, etc., which can be increased or decreased according to the customer's needs. Finally, it will be checked by OQC then packaged for shipment.

Note that up to this point it's still just the cell. The cells will be sent to a pack factory for further processing, including soldering circuit boards, packaging, etc.

The downstream of the pack factory is the various manufacturers, such as Apple, Lenovo, Huawei, they will take the battery pack to be installed in the terminal, then come to our consumers.

三

Advantages Differences

Cylindrical winding is a classical battery configuration, which has been used for a long time in NiMH 3C Li-ion batteries, the industry has accumulated a lot of experience in production design. The advantages of cylindrical winding include high productivity good consistency, while the disadvantages include low space utilization due to cylindrical shape temperature distribution due to poor radial thermal conductivity.

Due to the poor radial thermal conductivity of cylindrical batteries, the number of winding turns of the battery cannot be too many (the number of winding turns of 18650 batteries is generally around 20 turns), so the capacity of a single unit is small, a large number of monomers are needed to form battery modules packs when applied to electric vehicles, which greatly increases the connection loss management complexity.

Cylindrical wound batteries may look simple in appearance, but the inner design is not. Good battery design is a complex problem involving electrochemical, thermal, electrical, mechanical many other fields, which puts high dems on battery designers.

Example 1: The figure below shows the internal dimensions (unit: mm) of an 18650 battery, the combined length of the positive negative electrodes is nearly 1.5 meters, but the width of the lugs used to draw the current is only 4 mm. Battery designers need to carefully the lugs (position, number, etc.), electrode coating many other parameters, in order to reduce the uneven distribution of current on the plate, to reduce the uneven distribution of the temperature inside the battery.

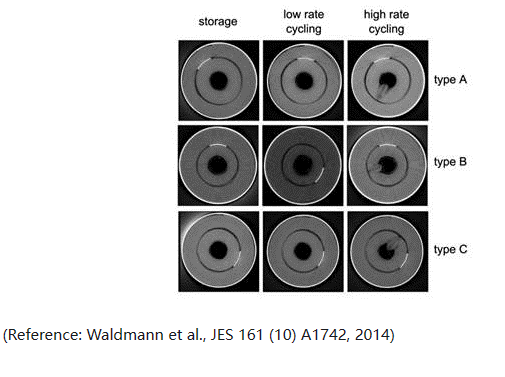

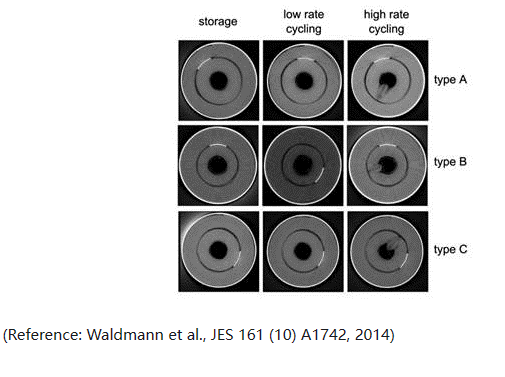

Example 2: One form of aging failure of cylindrical wound batteries during use is the warping of the wound pole pieces. The source of warping may be the inconsistent pace of volume change of the electrode layers during cycling.

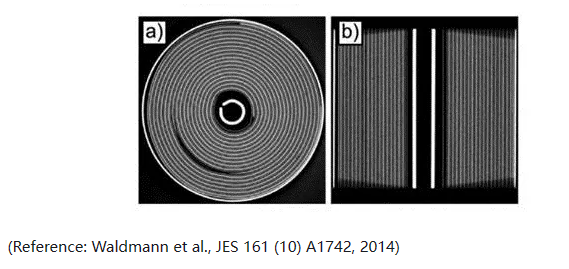

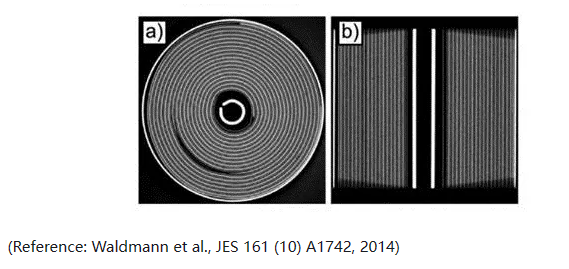

The following figure shows the electrode morphology of three 18650 batteries after storage, low rate cycling, high rate cycling taken with CT, the warping phenomenon can be clearly seen under high rate.

Unlike the wound type, which is formed by winding a single positive negative electrode, the laminated type is formed by stacking multiple layers of electrodes.

The advantages of the square laminated type include:

1) Thin thickness (generally no more than 1 cm due to the stamping strength of the aluminum-plastic film), so the heat dissipation performance is very good;

2) Multiple pole pieces, each of which has a flange welded to the pole lugs, resulting in good uniformity of current density distribution on the pole plate;

3) Thin film type, easy to form modules battery packs, high space utilization efficiency;

4) Aluminum-plastic film packaging is lightweight fits tightly with the cell after vacuuming, which is conducive to reducing invalid weight volume.

However, the disadvantages of this configuration include:

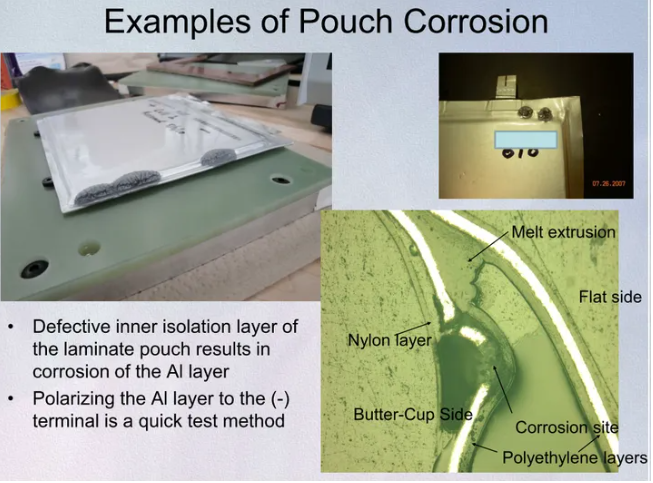

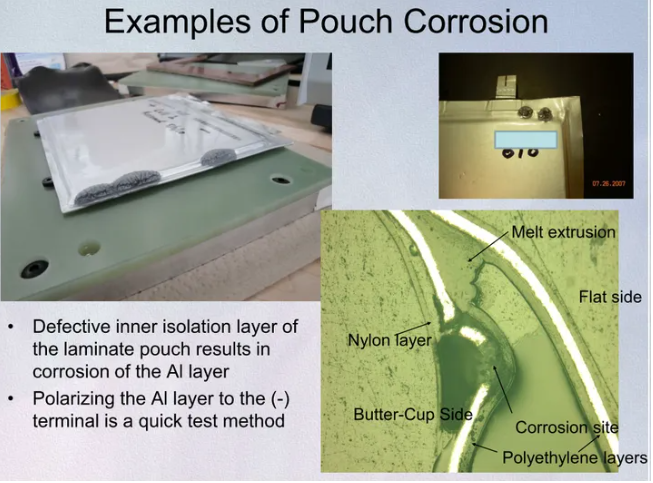

1) The long-term reliability of aluminum-plastic film packaging is more difficult to ensure, as shown in the following figure:

2) The cell body is softer, the contact impedance between the poles may be higher, which needs to be solved at the module level or battery pack level;

3) Lower production efficiency compared to coiled cells.

The square wound type combines the appearance characteristics of the square laminated type (but tends to be thicker) with the pole plate fabrication method of the cylindrical wound type, has the advantages of high space utilization high production efficiency. However, the design of this type of battery is also the most complex, with a large number of design variables to consider, as well as the fit between the the cell.

In summary, lithium battery aluminum , steel , plastic has its own advantages disadvantages, can not simply judge, look at the use of occasions, look at the judging criteria, lithium battery soft pack hard pack can only be said to be different, each with its own advantages disadvantages.