Based on the vast market of China's FPC, FPC in the cell phone electronics industry has entered the global stage of full competition, on the one h, the market space is more saturated; on the other h, the new energy vehicles as well as the outbreak of the power battery market, but also let the FPC looking for a new window of application.

"Old products new applications", which is the FPC now need to break through the new label.

Around this, this article analyzes the application of FPC in new energy vehicles.

I

FPC (Flexible Printed Circuit) Introduction

Flexible Printed Circuit (FPC, Flexible Printed Circuit) is a flexible copper-clad board as a substrate made of a circuit board, as a signal transmission medium used in the connection of electronic products, with a high density of wiring assembly, good bending, lightweight, process flexibility other characteristics.

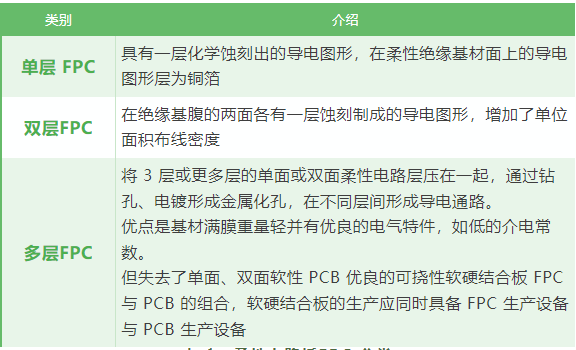

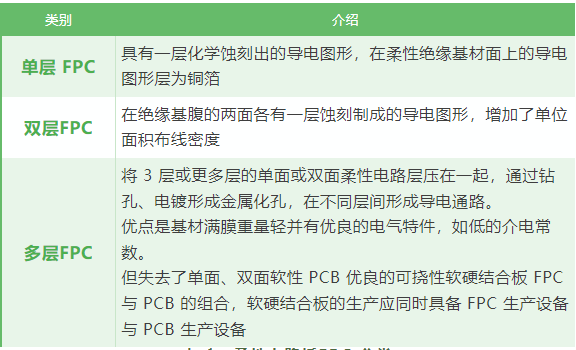

FPC is generally categorized into single-layer FPC, double-layer FPC, multi-layer FPC, rigid-flexible version.

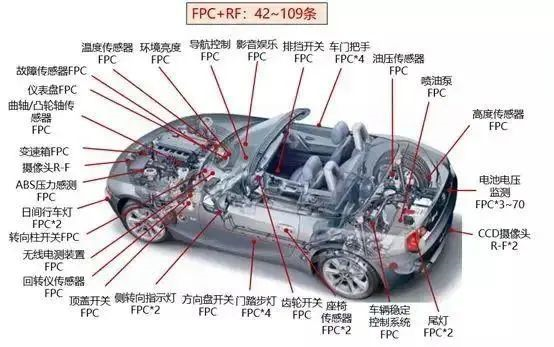

Figure 1: Characteristics of Flexible Circuit Board FPCs

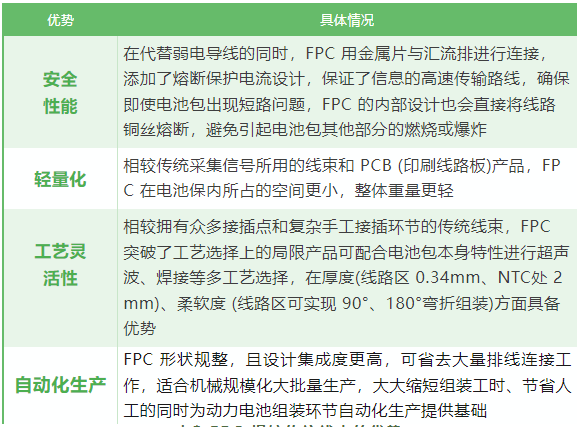

Table 1: Flexible Circuit Board FPC Classification

II

FPC Composition Production

The insulating film forms the base layer of the circuit the adhesive bonds the copper foil to the insulating layer.In multilayer designs, it is then bonded to the inner layer. They are also used as protective coverings to insulate circuits from dust moisture to reduce stress during flexing, with the copper foil forming the conductive layer.

There are many types of insulating film materials,but the most commonly used are polycoolimide polyester.Nearly 80% of all U.S. manufacturers of flexible circuits currently use polyimide film materials, about 20% employ polyester film materials. Polyimide materials are non-flammable, geometrically stable, have high tear strength, have the ability to withst soldering temperatures. Polyester, also known as polyethylene bisbenzene dicarboxylate (Polyethyleneterephthalate abbreviated as: PET), is physically similar to polyimide in that it has a low dielectric constant, absorbs very little moisture, but does not withst high temperatures. It has a low dielectric constant, absorbs very little moisture, but is not resistant to high temperatures.

Polyesters have a melting point of 250°C a glass transition temperature (Tg) of 80°C, which limits their use in applications requiring extensive end welding. In low temperature applications, they exhibit rigidity. Nevertheless, they are suitable for use in products such as telephones other products that do not require exposure to harsh environments. Polyimide insulating films are usually combined with polyimide or acrylic adhesives, polyester insulating materials are usually combined with polyester adhesives. The advantage of combining materials with the same properties is the dimensional stability after dry soldering or after several lamination cycles. Other important properties in adhesives are a low dielectric constant, a high insulation resistance, a high glass transition temperature a low moisture absorption.

In some flexible circuits, rigid members formed from aluminum or stainless steel are used, which provide dimensional stability, physical support for the placement of components wires, stress relief. An adhesive bonds the rigid member to the flexible circuit. Another material that is sometimes used in flexible circuits is the adhesive laminate, which is formed by coating both sides of an insulating film with an adhesive.Adhesive laminates provide environmental protection electrical insulation,as well as the ability to eliminate one film, the ability to bond multiple layers with fewer layers.

Copper foils are suitable for use in flexible circuits can be electrodeposited (ED) or plated. Electrodeposited copper foils have a shiny surface on one side, while the other side is processed to have a dull, non-glossy surface. It is a flexible material that can be made in many thicknesses widths, the non-glossy side of ED copper foil is often specially treated to improve its bonding ability. In addition to its flexibility, wrought copper foil is characterized by a hard, smooth surface, which makes it suitable for applications requiring dynamic flexing.

In addition to being used to bond insulating films to conductive materials, adhesives,It can also be used as a cover layer, as a protective coating, as a covering coating.The main difference between the two is the type of application used,with the overlay bonding covering the insulating film in order to form circuits in a stacked configuration.The screen printing technique used to apply the overlay of the adhesive. Not all overlay structures contain an adhesive. Stacks without adhesive form thinner circuits greater flexibility.It has a better thermal conductivity compared to laminated constructions using adhesives as a base. Due to the thin structural characteristics of adhesive-free flexible circuits, due to the elimination of the thermal resistance of the adhesive, which results in improved thermal conductivity. It can be used in operating environments where flexible circuits based on adhesive laminated structures cannot be used.

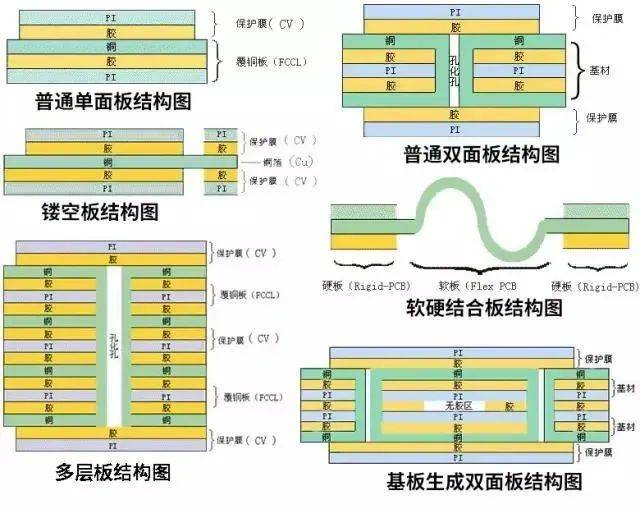

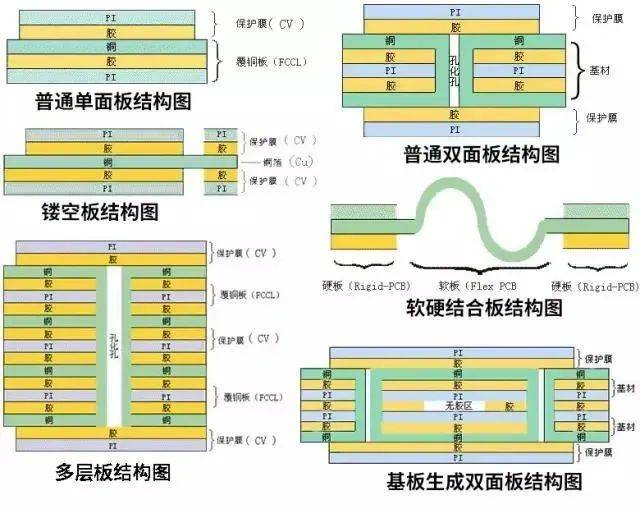

Figure 2: Six FPC structures

Copper Foil: Basically, there are two types of copper foil: electrolytic copper rolled copper. Common thicknesses are 1oz 1/2oz 1/3 oz.

Substrate Film: The common thicknesses are 1 mil 1/2 mil.

Adhesive: Thickness depends on customer's requirement.

Protective film: for surface insulation. Common thicknesses are 1 mil 1/2 mil.

Adhesive: Thickness depends on customer's requirement.

Release paper: Avoid foreign matter on the adhesive before pressing; easy to work.

Reinforcement board: Reinforce the mechanical strength of FPC to facilitate the surface mounting operation. Common thicknesses range from 3mil to 9mil.

Adhesive: Thickness depends on customer's requirement.

Release paper: to avoid adhesive in the pressure before the attachment of foreign objects.

EMI: Electromagnetic shielding film, to protect the circuit board lines from outside (strong electromagnetic area or susceptible to interference) interference.

Figure 3: FPC Production Flow

Three

FPC main application direction

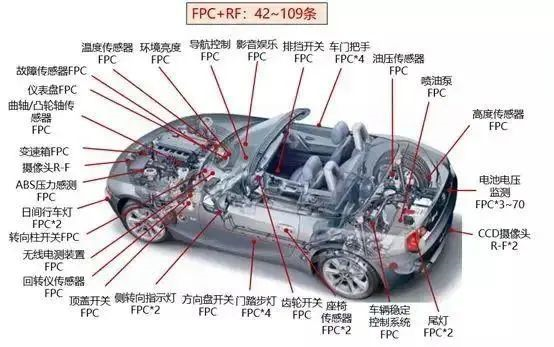

For automobiles,both fuel vehicles intelligent vehicles have a large number of FPC applications.Mainly present in the automotive electronics segment, automotive electronics is a general term for automotive electronic control devices automotive electronic control devices.

It mainly includes engine control system, chassis control system automotive electronic control system.

from structural, spatial other considerations ,the future of new energy vapor will certainly be a large number of FPC instead of wiring harness, will be applied in many parts of the vehicle to achieve. So FPC technology is a very important trend in automotive electronics,especially in smart cars, especially in the battery BMS, vehicle lighting system, door control system, camera module so on.

Generally an electric car will be up to more than 100 FPC applications, which belongs to the battery BMS in the FPC vehicle camera module application value is the highest, but also the focus of the development field.

When the FPC of the BMS is used in the battery, cost space are two important issues for the battery.

As far as current technology is concerned, battery capacity is basically maxed out. There is actually a limit to how many batteries can fit in a PACK utilizing FPC instead of traditional BMS wiring ensures stable performance while also reducing the risk of top cover friction from breathing.This is currently the dominant approach across the board.

Four

Application of FPC in new energy vehicles

The acquisition line is an important part of the BMS system for new energy vehicles.Realize the monitoring of new energy power battery cell voltage temperature; connected data acquisition transmission comes with overcurrent protection; protection of automotive power battery cell, abnormal short circuit automatic disconnection other functions.

Previously, the new energy vehicle power battery collection line using traditional copper wire harness program, the conventional wiring harness from the copper wire external surrounded by plastic become, connected to the battery pack, each harness to reach an electrode, when the power battery pack current signal is a lot of time, need a lot of wiring harnesses to cooperate with the space of the large crowded.

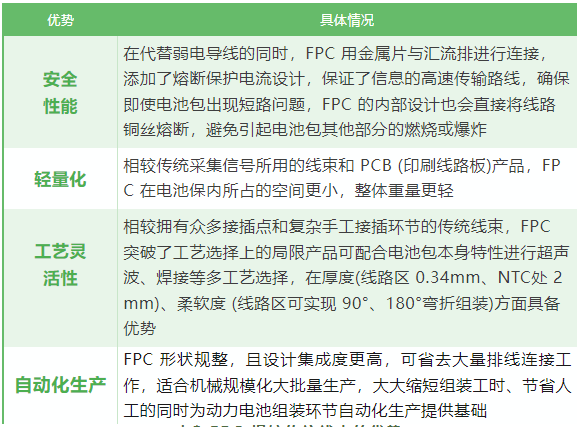

In the pack assembly process, traditional harnesses rely on workers to fix the ports on the pack manually, with a low degree of automation. Compared with the copper wire harness, FPC due to its high degree of integration, ultra-thin thickness, ultra-softness other characteristics, in terms of safety, lightweight, layout other aspects of the outsting advantages, in addition to the thin thickness of the FPC, the battery pack structure customized, the assembly can be gripped through the robotic arm directly placed on the battery pack, the degree of automation is high, suitable for large-scale mass production, the trend of FPC to replace the copper wire harness is clear.

FPC should have the following advantages in the power battery module:

high degree of integration

Since the embedded Fuse, connectors, chip NTC, aluminum / nickel terminals; not only to provide excellent consistent electrical performance, to meet the needs of smaller higher density installation of the design needs of three-degree space wiring the appearance can be changed in accordance with the limitations of the space for the development of high-density, miniaturization, the direction of the need for high-reliability, in order to achieve the integration of the assembly of the component the wire connection.

Automated assembly possible

Fast accurate assembly, conducive to the realization of automation; in the assembly fault tolerance here, can avoid a lot of wiring harness design due to manual errors, in the connector level also reduces a lot of ion error opportunities. The use of FPC sampling can reduce the Module integration process complexity, FPC battery busbar (busbar) connection can be automated welding, effectively reducing labor costs. Even if the customer can't realize the automated welding in the mature situation, using the traditional screw locking method, can still effectively reduce the labor investment.

0.34mm at line area, 2mm at NTC

The line area can be assembled with 90° 180° bends.

When used for the entire vehicle, it can reduce weight by about 1kg compared to the harness solution.

In terms of cost, the FPC itself is not very costly, there is a significant reduction in connection costs.

FPC VS Copper Wire Harness

Compared with copper wire harness, FPC due to its high degree of integration, ultra-thin thickness, ultra-softness other characteristics, in terms of safety, lightweight, layout other aspects of the outsting advantages, in addition to the FPC thickness is thin, the battery pack structure is customized, the assembly can be gripped by the robotic arm to be placed directly on the battery pack, the degree of automation is high, suitable for large-scale mass production, FPC to replace the copper wire harness trend is clear.

Table 2:Advantages of FPC over traditional wiring harnesses

In summary, the FPC solution has become the most important choice for most new models of new energy vehicles.FPC to CCS (Cells Contact System, integrated busbar, wiring harness board integrated parts) integration. CCS products by the FPC, plastic structural components, copper aluminum rows, etc., copper aluminum rows will be multiple cells through the laser welding for series parallel connection, FPC through the copper aluminum rows, plastic structural components connected to form an electrical connection signal detection structure components.

Generally speaking, soft pack hard pack batteries are different FPC program, the practice is not quite the same, including the end of the connector different connection forms have different programs (crimping, welding, etc.) FPC's biggest advantage lies in its flexibility, in that it can be upgraded with the iterative battery control technology will evolve a lot of forms, itself is also a customized product.

In the next chapter, we will continue to analyze the many options of FPC technology.