Introduction

The team leader is the executor of the enterprise management the leader of the team staff, plays the role of connecting the past the next in the enterprise.

The level of team leader management directly affects the quality of products, costs, delivery time, safety production staff morale. Therefore, in order to strengthen on-site management, team leaders should strive to improve their own quality level improve the comprehensive competitiveness of the team.

The team is strong, the enterprise is strong, on the morning of July 22, Shenzhen Huike New Materials Co., Ltd. carried out the "excellent monitor how to do field management" training course in Beihai base.

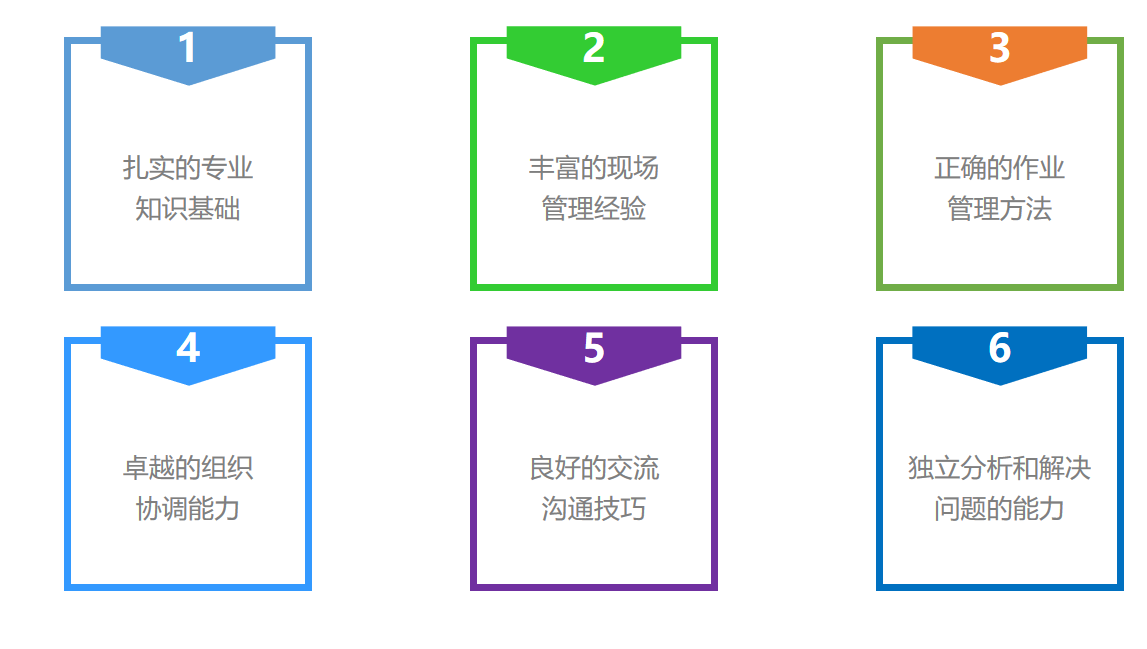

First, excellent basic management should have the ability

The team leader is not only the bridge between the previous the next, but also the link between employees leaders.

The team leader is not only the bridge between the previous the next, but also the link between employees leaders.

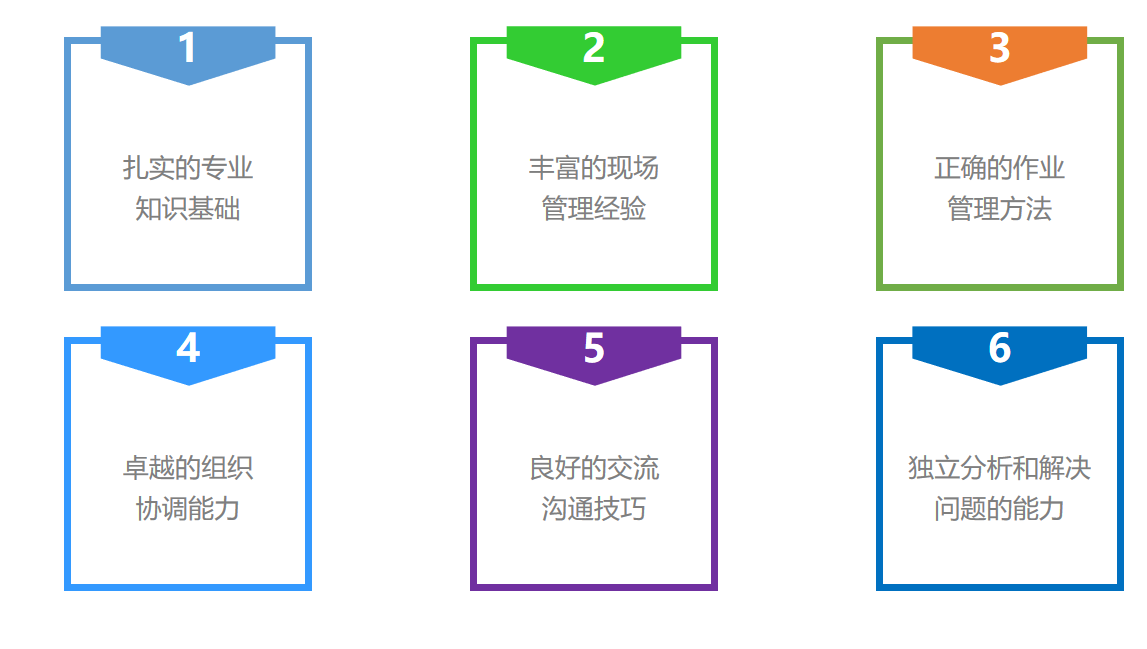

On how to become an excellent supervisor, monitor, production manager Gao Qingyou management is: only "six do", take you to do a good team leader!

Second, basic site management points

Manager Gao elaborated the main points of grass-roots site management from three aspects: management consciousness, management method work daily.

He believes that the manager is the person who completes the task realizes the management goal, so it is necessary to deliberately establish cultivate the manager's "field management consciousness" in the actual management work.

On the one h, the manager's field management consciousness is the most capable of correcting the deviation of self-work goals supervising the research formulation of self-work plans, programs, measures methods.

On the other h, the production site management is the core of quality management, but also the basic link of quality management, to do a good job in the production site quality control is an important work for each production enterprise.

"It helps to make safety rules regulations concrete, so that management has rules, work procedures actions have stards," Gao concluded.

Third, the core content of site management

Site management refers to the use of scientific management systems, stards methods for the production of various production factors on the production site, including people (workers managers), machines (equipment, tools, station appliances), materials (raw materials), methods (processing, testing methods), environment (environment), information (information), etc., reasonable effective planning, organization, coordination, control testing. Make it in a good combination state, to achieve the purpose of high quality, high efficiency, low consumption, balance, safety civilized production.

In this link, Manager Gao emphasized the key points of material management the management of operation methods. Based on science technology, rules regulations practical experience, with safety, quality efficiency as the goal, the operation process is improved, so as to form an optimized operation procedure, gradually achieve safe, accurate, efficient labor-saving operation effects.

The fourth site 5S management

"5S" originated in Japan, the main content: finishing (Seiri), cleaning (Seiton), cleaning (Seiso), cleaning (Seiketsu) literacy (Shitsuke) the abbreviation of the five words. Because the first letter of these five words in Japanese Romanization is "S", they are shortened to "5S".

5S has played a huge role in shaping the image of the company, reducing costs, on-time delivery, safe production, a high degree of stardization, creating a relaxing workplace, on-site improvement.

Therefore, Manager Gao repeatedly stressed that with the development of the world economy, 5S has become a new trend of enterprise site management, one of the management methods that cannot be ignored in enterprise site management.

Sum up

Field management is very important to the survival development of an enterprise. Shenzhen Huike New Materials Co., Ltd. aims to make managers employees realize that lean production management is not a job that can be completed at one time through this training. In the process of doing lean production, we should reasonably use various tools of site management, carry out continuous transformation on the site, continuously improve various waste phenomena. Only in this way can it be more in line with the core idea of lean production that is infinitely close to zero waste.

The promotion of site management requires the joint efforts of all employees. As managers, we are executors supervisors, but also to implement, track, implement, rectify, assess without discount.