NO. 1

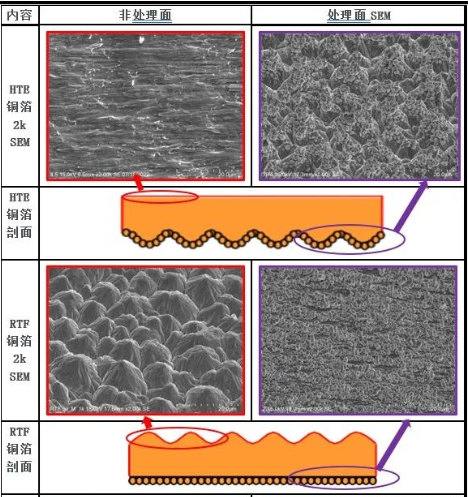

Definition of Inverted Copper Foil

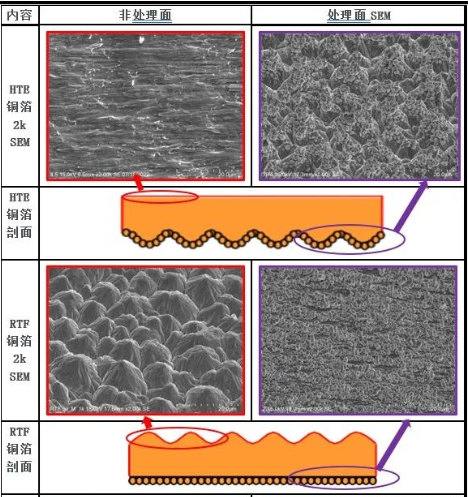

Conventional electrolytic copper foil has a glossy a rough surface, the rough surface is generally roughened, the rough surface is bonded to the resin substrate in general printed circuit production. Reverse copper foil, on the other h, the rough side of the copper foil is on the surface of the circuit board, which facilitates direct adhesion of the dry film with the future on this uniformly rough surface, good bonding can be obtained without other pre-treatment For this reason, the copper foil factory reverses the rough side roughs up the bright side of the copper foil to enhance the treatment, so that the copper foil is referred to as reverse copper foil, or also known as RTF copper foil.

Since the roughness of the glossy surface is very low, it is easier for the reverse-turned copper foil to be clean at all times in the production of fine lines, no side-etching phenomenon will be formed, which is conducive to the production of fine lines the improvement of the yield rate.

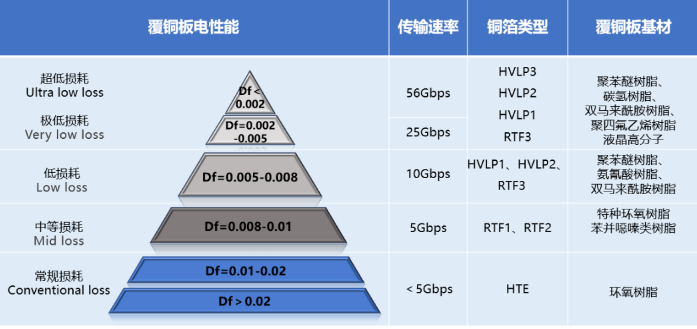

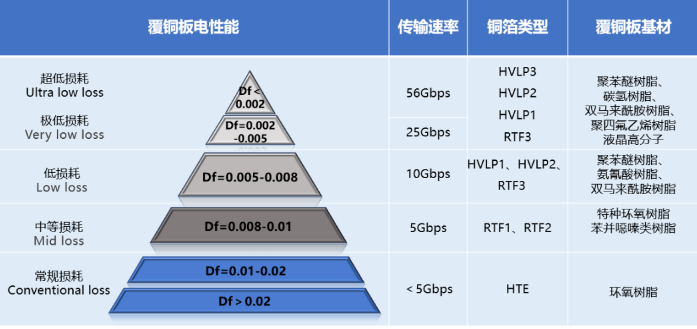

A large number of current gathered on the conductive surface, the more to the center of the conductor the smaller the current, a phenomenon known as the "skin effect". Due to the existence of the skin effect, high-speed PCB, if you continue to use conventional copper foil, the result is: with the increase in signal transmission frequency, the skin effect caused by the signal "distortion" is more more serious. As a result, the use of low roughness copper foils is becoming more more widespread in current high-speed materials.

Reversible copper foils (RTF) are generally categorized according to surface roughness as RTF1 (Rz ≤ 3.5 μm), RTF2 (Rz ≤ 2.3 μm) RTF3 (Rz ≤ 2.1 μm). Reversed (RTF) copper foils are used as stard for materials like Mid Loss materials Low Loss materials.

NO. 2

Characteristics of RTF Inverted Copper Foil

High conductivity: RTF inverted copper foil has remarkable conductivity with low resistivity excellent signal transmission performance, suitable for high-speed circuit design.

High Thermal Conductivity:RTF inverted copper foils have good thermal conductivity, which can effectively dissipate heat improve the heat dissipation performance of circuit boards.

Suitable for high-density interconnections: RTF inverted copper foils are suitable for high-density interconnection circuit board design, which can meet the needs of high-precision small-pitch connections.

Easy to process: RTF inverted copper foils have good processing adaptability can be stamped, cut, drilled other processing operations.

NO. 3

Application Scenarios for RTF Inverted Copper Foil

RTF Reverse Copper Foil is widely used in the manufacture of various types of circuit boards, including single-sided boards, double-sided boards, multilayer boards so on. Its main application scenarios include:

Communication electronics: RTF inverted copper foil is widely used in the field of communication electronics, such as base stations, routers, switches other equipment need to use RTF inverted copper foil.

Computer Hardware: RTF inverted copper foil is also used in computer hardware equipment such as CPUs, GPUs, motherboards, etc. for high-speed signal transmission heat dissipation.

Industrial control: RTF inverted copper foil is also widely used in industrial control field, such as various sensors, controllers, actuators other equipment need to use RTF inverted copper foil.

Automotive Electronics: In the field of automotive electronics, RTF inverted copper foil is mainly used in the manufacture of circuit boards for in-vehicle communication, navigation, engine control other systems.

NO. 4

Future Development Trends

As a key material in circuit board manufacturing, the performance manufacturing efficiency of RTF reversed copper foil are of great significance to the progress development of the entire circuit board industry.The technical barriers in the RTF copper foil industry are high, at present, Japanese Taiwanese companies dominate the global market. Local enterprises are deficient in the high-end field of electrolytic copper foil. On the whole, China's RTF copper foil industry still has huge development space.

Through the ion of excellent raw materials, optimization of production processes, strict quality testing technological innovation, the performance quality of RTF reversed copper foil can be continuously improved to meet the needs of the evolving electronics industry. At the same time, paying attention to environmental protection promoting the sustainable development of RTF reversing copper foil industry are also the directions we need to pay attention to make efforts.